Granulated Sugar in Food Manufacturing: Roles, Challenges & Smarter Alternatives

December 11, 2025

Granulated sugar remains one of the most widely used ingredients in commercial food and beverage manufacturing. Despite rising demand for reduced sugar formulations, manufacturers still rely on sugar for functionality that extends far beyond sweetness.

For B2B producers, refiners, and product developers, understanding the structural role of granulated sugar is essential for efficient reformulation, process optimization, and category innovation. Yet balancing sugar’s technical benefits with modern nutritional expectations requires strategic precision.

This article explores sugar’s multifaceted industrial roles, supply chain dynamics, formulation bottlenecks, sustainability considerations, and emerging alternatives that food manufacturers are rapidly adopting. It also connects these insights directly to fiber-first and functional ingredient solutions offered by Satoria Nutrisentials.

Why Granulated Sugar Still Matters in Industrial Food Manufacturing

Sugar is often perceived simply as a sweetener. However, in commercial manufacturing, it acts as a bulking agent, preservative, humectant, fermentation fuel, texture regulator, browning catalyst, and freezing point modifier.

Granulated sugar contributes to stability and structure in ways alternative sweeteners often struggle to replace without formulation adjustments. Removing sugar from industrial recipes can impact viscosity, crystallization control, shelf stability, color, mouthfeel, and process output.

Regulatory pressure, market demand, and clean label expectations are now prompting food manufacturers to assess sugar reduction without disrupting their product performance or production efficiency.

The Structural Role of Granulated Sugar in Production Workflows

Sugar plays a measurable impact on physical, chemical, and biological processing across factory environments. Many products depend on sugar’s granular structure to influence dissolution behavior, hydration rate, aeration retention, heat transfer, reaction time, and viscosity equilibrium.

Sweetness Is Just One Layer of Its Function

In industrial formulations, sweetness is sugar’s smallest responsibility. Its true value lies in performance engineering:

- Humectant effect for moisture control and soft texture preservation

- Glass transition support in baked goods to structure dough elasticity

- Freezing point depression in ice cream and cold desserts

- Crystallization behavior that determines grittiness, spreadability, and smoothness

- Thermal reactions enabling predictable browning

- Caramelization and Maillard activation for color and aroma

- Density and bulk control supporting final product weight, mouthfeel, and volume

Sugar’s granular form makes it ideal for dry blending, large-scale cooking vats, beverage tanks, and fermentation arms.

Preservation & Moisture Balance at Scale

Sugar stabilizes moisture by binding free water, limiting microbial proliferation. In mass production, sugar maintains relative water activity to minimize spoilage without refrigeration-dependent interventions.

Granulated sugar helps reduce product brittleness, prevent premature staling, and extend shelf viability. Its water-binding behavior makes it essential in products where predictable moisture retention determines category success.

Food manufacturers often struggle to substitute sugar without compromising shelf protection or soft texture. This gap has created growing demand for sugar reduction technologies that restore sugar-like bulk without glycemic disruption.

Consistency, Flowability & Batch Precision

Granulated sugar is mechanically stable, making it optimal for pneumatic transfer systems, hopper flow, silo storage, volumetric feeders, batch scales, mixers, and automated lines.

Industrial operators value sugar’s predictable flowability, density, particle size uniformity, and dry blend compatibility. These characteristics ensure batch-to-batch reliability with minimal production line interference or cleaning complexity.

However, sugar reduction reformulations can disrupt powder behavior, blend cohesion, and inflation properties of baked goods.

How Sugar Influences Aroma, Color & Consumer Sensory Expectations

Sugar is the central driver of factory-optimized browning and aroma release in baked goods, confections, sauces, and beverages. Manufacturers design recipes around sugar to ensure predictable end-product sensory experiences.

Maillard Reaction: Sugar’s Most Underrated Industrial Power

Granulated sugar contributes reducing sugars needed for Maillard activation, accelerating aroma formation and browning kinetics for:

- Bread crust development

- Biscuit aroma complexity

- Coffee and roasted beverage notes

- Caramel-like flavors in sauces

- Cocoa and dairy product aroma release

- Savory glaze formation

In large-scale food plants, sugar controls reaction time, heat transfer efficiency, and color uniformity.

Color Uniformity & Thermal Confidence

Granulated sugar supports predictable caramelization thresholds, ensuring consistent color shading across batches. This is why sugar reduction reformulations must be approached with caution—without it, products can appear pale, flat, or aromatically incomplete.

This has prompted manufacturers to leverage functional fibers and proteins that restore process browning behavior without sugar overdose.

Global Supply Chain & Sustainability Lens on Granulated Sugar

For B2B buyers, sugar supply isn’t just about cost—it’s also about logistics, sustainability, traceability, warehouse behavior, storage lifespan, humidity resilience, and seasonality risk.

Supply Chain Resilience Challenges

Granulated sugar production suffers from fluctuating risks including:

- Climate vulnerability reducing cane or beet output

- Transportation bottlenecks impacting delivery schedules

- Market volatility affecting long-term procurement costs

- Warehouse humidity sensitivity causing clumping or crusting

- Silo storage challenges requiring regular flow agitation

Food manufacturers are now evaluating alternatives that stabilize bulk and reduce sugar dependency while providing gut health benefits.

Sustainability & Manufacturing Efficiency Demands

Major food corporations are pressured to meet sustainability goals, even for commodity sweeteners like sugar. The environmental strain of sugar production has led manufacturers to pair sugar reduction with high-impact functional fibers or plant protein fortification to increase nutritional value without expanding ingredient volume.

Satoria Nutrisentials supports this movement with clean label, halal-certified functional ingredients that reduce formulation trade-offs when lowering sugar.

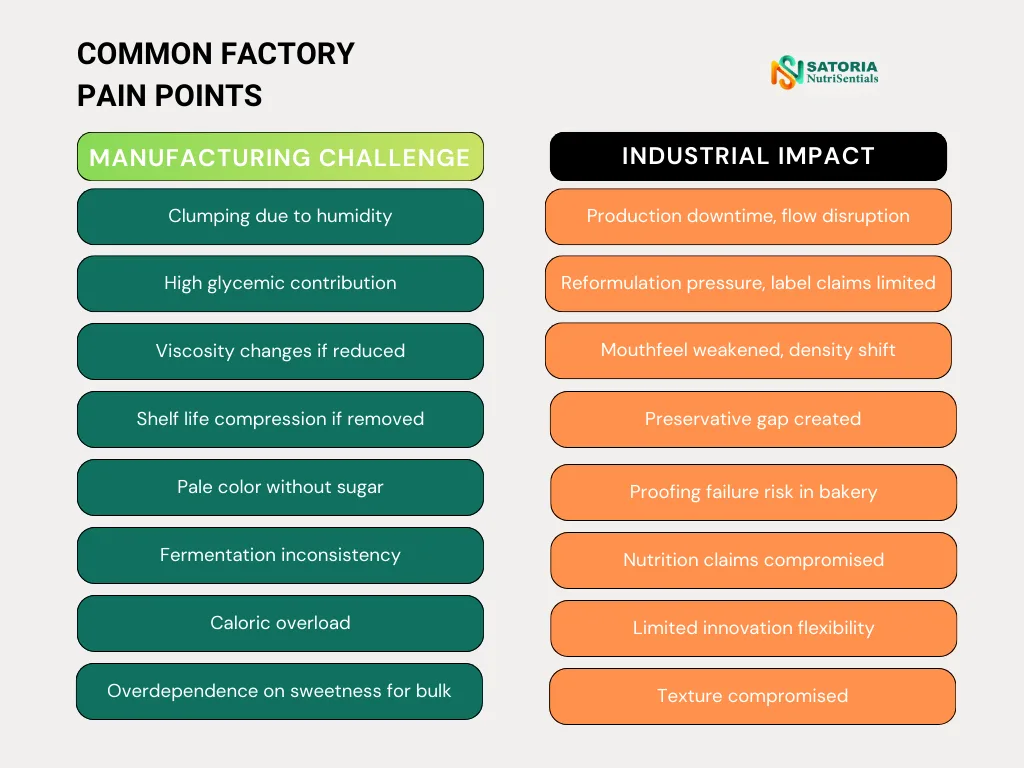

Key Manufacturing Challenges When Using Granulated Sugar at Scale

It’s easy to add sugar but difficult to remove it. B2B manufacturers face recurring challenges in sugar-centric production including humidity control, crystallization regulation, caloric density creep, equipment clogging, viscosity imbalance, and fermentation inconsistency.

These challenges clarify why sugar reduction strategies now increasingly center around functional fibers like resistant dextrin.

Resistant dextrin provides sugar-mimicking bulk, supports shelf stability, works under acidic or heated conditions, and adds dietary fiber without altering taste quality.

Smarter Sugar Reduction with Functional Fibers & Plant Protein Fortification

Food manufacturers are rapidly adopting sugar reduction frameworks that maintain bulk while improving gut health positioning.

Resistant Dextrin: The Strategic Infrastructure for Sugar Reduction

Resistant dextrin delivers critical improvements in industrial reformulation:

- Acts as a sugar-like textural bulking system

- Stabilizes viscosity in beverage production

- Maintains clarity and smooth mouthfeel

- Enhances fortification of soft baked goods

- Activates Maillard-like browning support

- Improves digestive tolerance compared to inulin

- Neutral taste and no aftertaste impact

- Suitable for industrial pipelines for sauces, beverages, and bakery

- High solubility without mouthfeel change

- Acid and heat stable for large-scale processing

In many ice cream, sauce, syrup, and drink reformulations, resistant dextrin has proven easier to work with than inulin because of its better digestive tolerance and process stability.

Satoria Nutrisentials supplies high performance clean label fibers that support sugar reduction bottlenecks without impacting sensory or production confidence.

Combining Sugar Reduction + Pea Protein for Better Market Positioning

Beyond fiber, plant protein fortification is a key strategy for B2B manufacturers.

Granulated sugar reduction paired with pea protein isolate or pea protein concentrate can improve labeling, mouthfeel, structure, protein content, and satiety positioning. This combination gives manufacturers more flexibility for “added nutrition” claims alongside sugar-lowering strategies.

Satoria’s plant protein portfolio includes highly functional granular blending solutions that complement sugar reduction frameworks.

How Satoria Nutrisentials Supports Sugar Innovation & Reformulation Confidence

Satoria Nutrisentials offers high-impact functional ingredients that manufacturers can integrate to reduce sugar dependency while retaining production confidence.

Key solutions include but are not limited to:

- Resistant Dextrin with high solubility and clarity

- Granular Plant Proteins (Pea Protein & Pea Protein Isolate)

- Clean Label Nutrition Ingredients for functional reformulation

- Halal Certified Industrial Ingredient Portfolio

- Fiber-Driven Blends for sugar-reduced category modernization

Their products are tailored for manufacturers pivoting to low-glycemic formulations, enhanced gut health claims, improved mouthfeel, soft texture retention, moisture regulation, and industrial stability improvements.

Manufacturers Want to Reduce Sugar — But They Still Need Its Function Back

When manufacturers reduce granulated sugar, they need the 3 pillars restored in formulation:

- Structure and bulk

- Stability and preservation

- Sensory and thermal confidence

Replacing sweetness is easy. Replacing bulk, browning behavior, humectancy, and viscosity stability is not.

This is why the industry is shifting toward fibers like resistant dextrin that restore technical sugar function while offering modern nutrition claims.

Next Steps: Build the Future With Smarter Formulation

Ready to reformulate for better stability, tolerance, and gut performance? Let’s talk.

Scale Nutrition Without Breaking the Process

Manufacturing shouldn’t lose clarity because sweetness is lowered.

Satoria’s functional fibers and pea proteins are built for scale. They restore bulk, viscosity, and processing resilience without aftertaste or digestive compromise.

Let’s engineer the next generation of formulations together.

Formulate Smarter, Scale Faster with Satoria Nutrisentials

If your team is considering sugar reformulation strategies for any product category—bakery, beverages, sauces, confections, dairy, or frozen desserts—Satoria has functional ingredient solutions that meet both process and nutritional demand.

Turn sugar dependency into strategic flexibility and meet modern consumer expectations without disrupting your production line.

Partner for Reformulation Confidence

Let’s explore how Satoria’s fibers and pea proteins can reinforce your next product innovation with better digestive tolerance, Maillard support, clarity, low glycemic impact, and industrial stability.

Get in touch today to explore partnership, trials, or product integration.

References

- Chetana, R., & Reddy, S. Y. (2020). Functionality of sugar in food processing and product texture development. Journal of Food Science and Technology.

- Goldfein, K. R., & Slavin, J. L. (2015). Why sugar’s functionality is difficult to replace in food manufacturing. Nutrition Journal.

- Mitchell, H. (2006). Sugar’s role in Maillard browning and aroma compound activation. Food Chemistry.

- Satoria Nutrisentials. (2025). Resistant dextrin for sugar reduction formulations. Internal product documentation.

- Struck, S., Jaros, D., & Brenner, T. (2014). Sugar reduction challenges in bakery and frozen dessert manufacturing. International Journal of Food Properties.