Clean Label Food Ingredients: Functional, Scalable, and Ready for Modern Formulations

November 15, 2025

Introduction

In a global market increasingly driven by consumer demand for transparency, “clean label” has become a defining standard in food and beverage innovation. For manufacturers, it’s no longer just a marketing claim—it’s a formulation and sourcing priority.

At Satoria NutriSentials, we understand that R&D and procurement teams face the challenge of replacing artificial or highly processed inputs with clean label food ingredients that still deliver performance, consistency, and compliance. Our portfolio—ranging from resistant dextrin to plant-based proteins and natural sweeteners—has been developed to help manufacturers meet that challenge with confidence.

This article outlines the technical characteristics, functional advantages, and formulation applications of clean-label ingredients, and how partnering with Satoria NutriSentials supports innovation and operational efficiency.

Understanding the Clean Label Concept in Manufacturing

Beyond Simplicity: Technical Definition

In formulation terms, clean label means using ingredients that are:

- Recognisable and easy to declare on packaging

- Free from artificial colours, flavours, or preservatives

- Derived from natural, minimally processed sources

- Supported by quality and safety certifications

For manufacturers, clean label is as much about ingredient transparency and traceability as it is about consumer perception. Every material added to a formulation must have a clear, compliant identity and a traceable origin—qualities that are integral to Satoria NutriSentials’ production systems.

The Manufacturing Perspective

Clean label formulation is a balance between compliance, performance, and cost efficiency. While consumers demand shorter labels, product developers must ensure that removing traditional additives doesn’t compromise processing performance, stability, or sensory quality.

That’s where functional clean label ingredients become critical—materials that not only look good on paper but also perform under commercial manufacturing conditions.

Functional Clean Label Food Ingredients

Resistant Dextrin – Clean Label Soluble Fibre

Resistant dextrin is one of the most versatile clean label functional fibres. Produced through controlled hydrolysis of starch, it offers:

- High solubility in water and excellent process stability

- Neutral taste profile suitable for beverages and snacks

- Functionality as a mild stabiliser and bulking agent

- Clean labelling as “soluble dietary fibre” or “resistant dextrin”

From a production standpoint, resistant dextrin can help replace synthetic stabilisers or texture modifiers while adding nutritional value. Satoria NutriSentials’ Fiberfit™ variant is engineered for compatibility with a broad range of pH conditions and thermal processes, making it ideal for RTD beverages, bars, and fortified foods.

Pea Protein and Pea Protein Isolate – Plant-Based Protein with High Functionality

Pea protein offers a clean-label alternative to dairy or soy proteins. Key technical advantages include:

- High protein concentration with balanced amino acid profile

- Neutral taste and high dispersibility

- Suitable for gluten-free, vegan, and allergen-controlled systems

- Non-GMO and produced through physical separation, not chemical extraction

From a manufacturing perspective, pea protein’s high solubility supports easy integration into powder blends, RTD beverages, or baked applications without affecting viscosity or mouthfeel.

Satoria NutriSentials’ Pea Protein and Pea Protein Isolate are processed under strict FSSC 22000, ISO 9001, and Halal-certified facilities, ensuring consistent batch quality and compliance for global export.

Rice Protein Isolate – Clean Source with Complete Functionality

Rice protein isolate delivers complementary amino acids to pea protein, making it suitable for multi-source protein formulations. It offers:

- Excellent dispersibility and emulsification properties

- Hypoallergenic and gluten-free characteristics

- Compatibility with high-heat processing

Ideal for sports nutrition, plant-based dairy, and baked applications, rice protein isolates can enhance protein content without affecting sensory properties.

Satoria NutriSentials sources rice proteins from non-GMO crops using gentle enzymatic processes, ensuring minimal denaturation and clean-label declaration.

Natural Sweeteners – SweetSentials™, Rice Syrup, and Tapioca Syrup

Sugar reduction continues to be one of the most complex challenges in product reformulation. Clean-label sweeteners must replicate sucrose functionality—taste, browning, and viscosity—without artificial additives.

Satoria NutriSentials offers several clean alternatives:

- SweetSentials™: a low-calorie sugar alternative with high sweetness equivalence and good thermal stability.

- Rice Syrup & Tapioca Syrup: natural sweetening solutions derived from enzymatically processed starch, providing binding, sweetness, and gloss in bakery and confectionery applications.

Each option maintains a clean ingredient declaration and stable performance across industrial processing conditions.

Maltodextrins (Pea & Rice) – Neutral-Profile Carbohydrate Solutions

Unlike conventional corn-based maltodextrins, pea and rice maltodextrins offer a clean label positioning and improved digestibility profile. They provide:

- Neutral flavour and high solubility

- Functionality as a carrier, bulking agent, or viscosity regulator

- Alternative carbohydrate sources for allergen-sensitive formulations

These materials are especially suitable for spray-dried products, instant beverages, and powdered flavour systems.

Technical Advantages of Satoria NutriSentials’ Ingredient Range

Consistency and Scalability

Our manufacturing capabilities ensure high-volume consistency with scalable supply options—crucial for brands moving from pilot formulation to industrial production. We support OEM and toll-manufacturing partnerships, enabling seamless integration into your supply chain.

Compatibility and Processing Stability

All Satoria NutriSentials’ clean-label food ingredients are developed with process performance in mind. They demonstrate:

- Excellent solubility and dispersion in both hot and cold systems

- Compatibility with thermal and shear-sensitive processes

- Stable performance across various pH levels

- Minimal impact on taste or colour profiles

This ensures reliable processing outcomes during extrusion, UHT, or blending operations.

Certification and Traceability

Every batch is backed by complete documentation and quality assurance. Our facilities comply with:

- FSSC 22000 Food Safety System Certification

- ISO 9001 Quality Management Systems

- Halal & Kosher certifications

- Non-GMO and allergen-free product declarations

Traceability and documentation support are available for all export markets, simplifying compliance with regional regulatory requirements.

Technical Support and Formulation Assistance

Satoria NutriSentials collaborates closely with product developers, providing application support, sample testing, and formulation troubleshooting. Our team can help you identify optimal inclusion rates, manage sensory challenges, and ensure your final product meets both functional and clean-label targets.

Application Insights

Beverages

- Resistant dextrin for fibre enrichment and stability in low-pH systems.

- Pea protein for plant-based, high-protein drinks with good solubility and mouthfeel.

- Natural sweeteners for reduced-sugar functional beverages.

Bakery & Confectionery

- Rice syrup for binding and gloss.

- Pea maltodextrin for volume and texture improvement.

- SweetSentials™ for sugar reduction without bitterness or off-notes.

Nutrition Bars & Meal Replacements

- Pea + rice protein blends for complete amino acid profiles.

- Resistant dextrin for dietary fibre enhancement and improved bar texture.

- Tapioca syrup for natural binding and sweetness.

Dairy Alternatives

- Pea protein isolate to replace casein or whey proteins.

- Rice protein for smoother mouthfeel and improved emulsion stability.

- Natural sweeteners for balanced sweetness and calorie reduction.

Functional Foods & Supplements

- Resistant dextrin for prebiotic and digestive-health claims.

- Rice maltodextrin as a clean-label carrier for flavours or active ingredients.

Implementation Strategy for Manufacturers

Step 1: Review Ingredient List and Identify Synthetic Inputs

Evaluate current formulations and identify components that can be replaced with natural or minimally processed alternatives. Common candidates include synthetic stabilisers, emulsifiers, and high-intensity artificial sweeteners.

Step 2: Conduct Bench-Scale Testing

Start with small-batch trials to test performance under your specific processing conditions—temperature, pH, shear, and hold time. Satoria NutriSentials provides technical documentation and formulation guidance to streamline this step.

Step 3: Validate Sensory and Shelf-Life Stability

Compare reformulated prototypes for texture, flavour, and stability against existing SKUs. Clean label ingredients such as resistant dextrin and pea protein offer stability comparable to conventional inputs when correctly balanced.

Step 4: Ensure Regulatory Alignment

All Satoria NutriSentials ingredients are compliant with major international food-safety standards. Our documentation packages include specification sheets, certificates of analysis, and declaration statements for global export readiness.

Step 5: Scale and Integrate into Production

Once validated, scale up using consistent batch supply. Our global logistics and industrial capacity ensure timely delivery and continuity of supply during commercialisation.

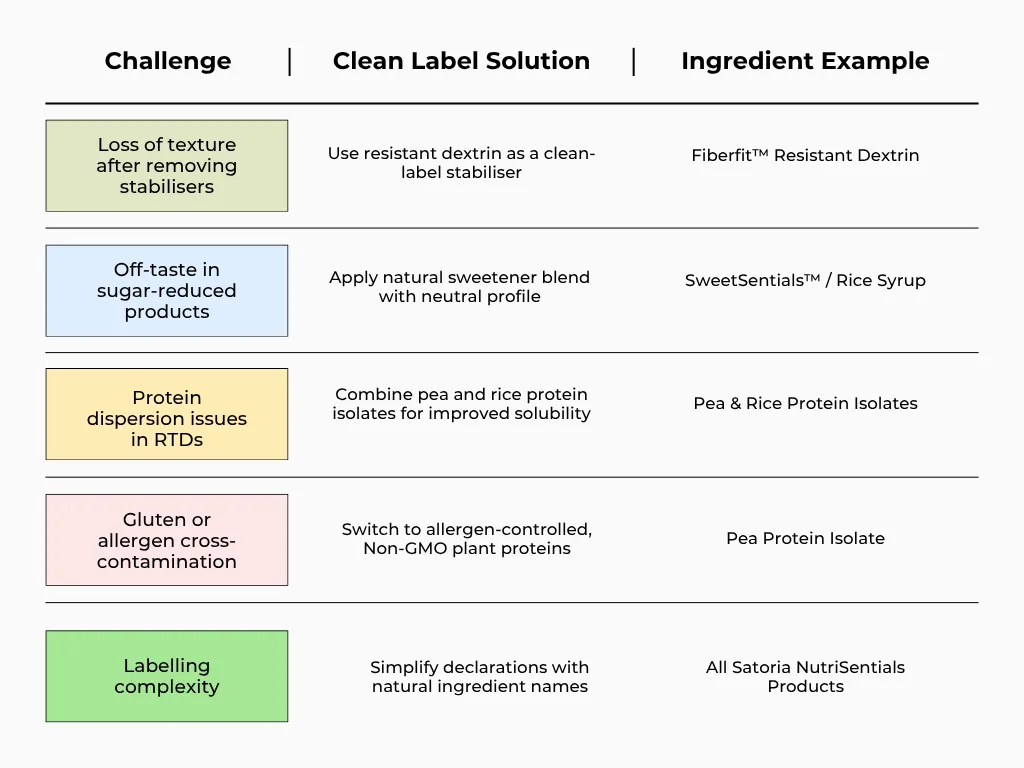

Common Formulation Challenges and Solutions

Partnership Advantages with Satoria NutriSentials

Integrated Manufacturing and R&D

Our facilities combine advanced production lines with continuous R&D capability, allowing us to tailor ingredient specifications to your process requirements.

Global Market Readiness

Satoria NutriSentials supplies functional ingredients to partners across the Asia-Pacific, Middle East, and European markets. Our export documentation and logistics partners ensure smooth customs clearance and stable global distribution.

Technical Collaboration

We work closely with formulation scientists and procurement managers to co-develop ingredient solutions that align with your brand’s operational, regulatory, and commercial objectives.

Advancing Clean Label Innovation Together

Clean label formulation is not just a response to consumer demand—it’s a technical evolution that demands collaboration between ingredient suppliers and manufacturers. By leveraging Satoria NutriSentials’ portfolio of high-performance, traceable, and compliant ingredients, manufacturers can simplify label declarations, enhance product functionality, and maintain large-scale efficiency.

Partner with Satoria NutriSentials

Whether you are reformulating an existing product line or developing a new clean-label innovation, Satoria NutriSentials is ready to support your project.

Our team can assist with:

- Ingredient selection and specification matching

- Pilot-scale sampling and application testing

- Technical and documentation support for regulatory compliance

- OEM or toll-manufacturing partnerships

Discover our full range of functional, clean label food ingredients at SatoriaNutrisentials.com/products or contact our team directly for consultation.

References

- Johnson, A. M., & Smith, B. D. (2024). Plant-based proteins: Formulation performance and industrial applications. Journal of Food Science & Technology, 59(4), 1123–1132.

- Lee, H., & Kim, J. (2025). Dietary fibre innovation: Resistant dextrin in functional foods. Food & Nutrition Research, 69(1), 45–58.

- Satoria NutriSentials. (2025). Products. Retrieved from https://satorianutrisentials.com/products/

- Satoria NutriSentials. (2025). How Resistant Dextrin Supports Gut Health and Stability. Retrieved from https://satorianutrisentials.com/article/resistant-dextrin-prebiotic/

- Wood, R., & Patel, S. (2024). Natural sweeteners in reduced-sugar formulations: Functional implications. International Journal of Food Science, 59(2), 321–335.